Reengineering and final maintenance: the CFL Z2s ready for their next adventure

After transporting customers for more than thirty years, 20 CFL Z2 railcars are preparing to set off for Romania to operate there. Here’s a look back at the preparations for this departure, which highlight the expertise and intrapreneurial spirit of CFL’s staff.

A characteristic atmosphere. Familiar sounds. And a natural setting that could be appreciated through the windows of this 1990 model. For many CFL customers, the CFL 2000 series of multiple units, otherwise known as the Z2, was an integral part of their mobility habits.

Continuous improvement, modernising their services and increasing their capacity to take care of customers, with that in mind, the CFL have been putting into service since 29 September 2024 their new fleet of Coradia trains.

The Coradias are arriving, the Z2s are leaving. From the beginning of 2025, 20 Z2 multiple units will gradually operate a Romanian railway company, which acquired them. The 21st will remain in Luxembourg for railway heritage purposes.

Essential parts recreated…from scratch

This planned replacement of the Z2s has once again demonstrated the spirit of initiative and innovation that is characteristic of CFL staff, particularly when it comes to anticipating the lack of a part that is essential to the operation of a machine.

‘Ensuring a reserve of certain parts proved tricky for this model of train, which is over thirty years old. We therefore had to find an alternative and resort to ‘reengineering’, in other words putting a new series of parts into production on our own initiative’, explains Grégory Kuchler, Passenger Equipment Projects Specialist at the CFL Maintenance Centre.

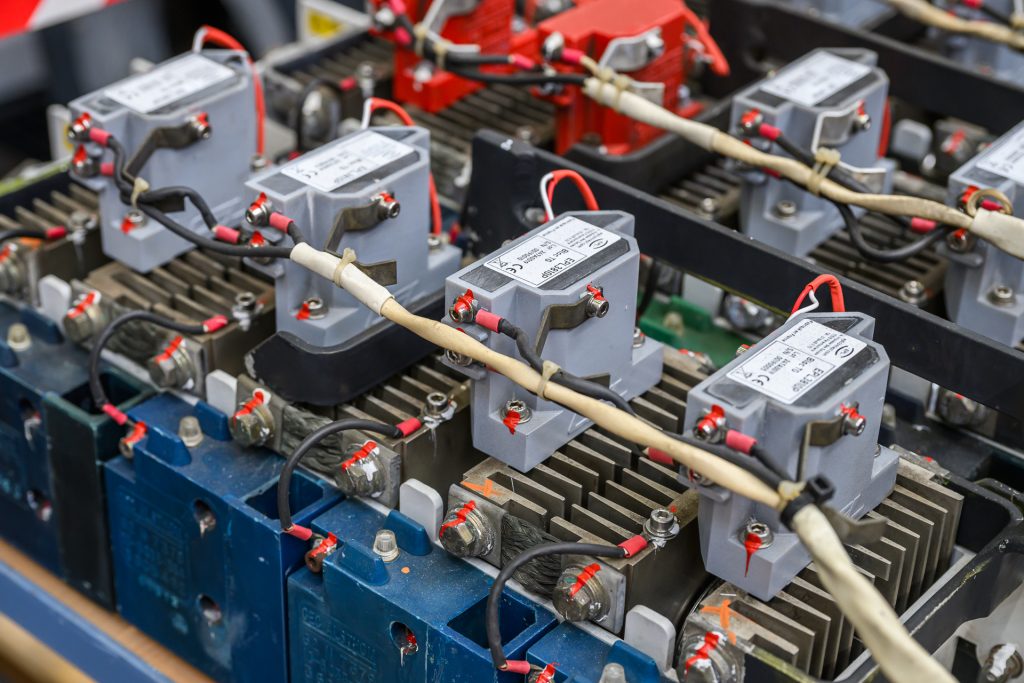

With his colleague Christian Schäfer, Traction Systems Technical Manager, he shows us the technical block that controls the power section of the railcars. This is an exact copy of the original unit created by CFL and their French supplier EPL Concept. Knowing that 24 such units are essential for the train to run, having a sufficient reserve was a question of service continuity.

‘First of all, we gathered together the documentation on these parts, which are over thirty years old. We used this paper documentation to draw up the specifications, this time in digital format, for the French supplier who validated the prototype technical block following a whole series of tests’, explains Christian Schäfer.

Within four months, the operation was complete, thanks to the efforts of the manufacturer and the CFL teams, who in turn carried out conclusive tests based on the prototype supplied.

‘We succeeded in recreating different types of parts by relying on the participation of everyone in our teams. With a shared will and motivation, we can achieve ambitious goals,’ adds Grégory Kuchler. We’re particularly proud of our work because we completed this reengineering project with no external expertise other than that of the supplier. It was an extremely rewarding experience for our maintenance engineering centre.

Between nostalgia and pride

The Z2 railcars have seen several generations of customers. And so have the railwaymen and women responsible for their operation, maintenance and upkeep.

‘We’re always a little nostalgic when a series of rolling stock is retired or leaves us, especially the Z2s, which have provided invaluable service with total reliability, thanks in particular to our total mastery of their operation and maintenance,’ says Guy Forette, Head of the Passenger Rolling Stock Division in the CFL Central Workshop. ‘During the thirty years or so that the Z2s have been in operation, one of the challenges has been to ensure that the knowledge of these machines is passed on from one generation of railwaymen to the next, which we have succeeded in doing right up to the end.’

Two teams of seven people from the CFL Central Workshop were working shifts to maintain and service the 21 Z2 railcars, with the support of colleagues who were experts in their respective fields. These experienced rolling stock staff, who worked passionately on the Z2s, will now be able to devote their time to the new generation of CFL trains, thanks to new training.

Constant commitment, a proactive mindset and well-honed procedures have ensured that the Z2s are ready for departure with a mission accomplished for the CFL: to hand over these multiple units to their new owner without any traffic restrictions, in an impeccable state of safety – the CFL’s absolute priority – and quality of service.

Pulled from the German border by a self-propelled unit from the Romanian freight company, the first four Z2s are leaving Luxembourg in the first half of 2025. The 16 others will follow the same route throughout the year, always in convoys of four.