The CFL’s Coradia Trains Come to Life in Alstom’s “Cathedral”

Assembled like a giant puzzle, the 34 new CFL Coradia trains are the result of a unique blend of craftsmanship, technical expertise, and cutting-edge technology. A visual and numerical journey into the “cathedral,” Alstom’s production unit located near Barcelona.

Alstom’s factory in Santa Perpètua de Mogoda, about 23 km from Barcelona, is considered Spain’s first Industry 4.0 site. Spanning 340,000 m², with 65,000 m² dedicated to production, modern mobility is crafted here every day. One in three trains running in Spain bears the ALSTOM name, whether urban, long-distance, or suburban trains.

Since 1994, this factory has been Spain’s flagship for railway manufacturing. As large as the Vatican, this “cathedral,” as the teams call it, boasts impressive dimensions—and easily meets the daily goal of 10,000 steps.

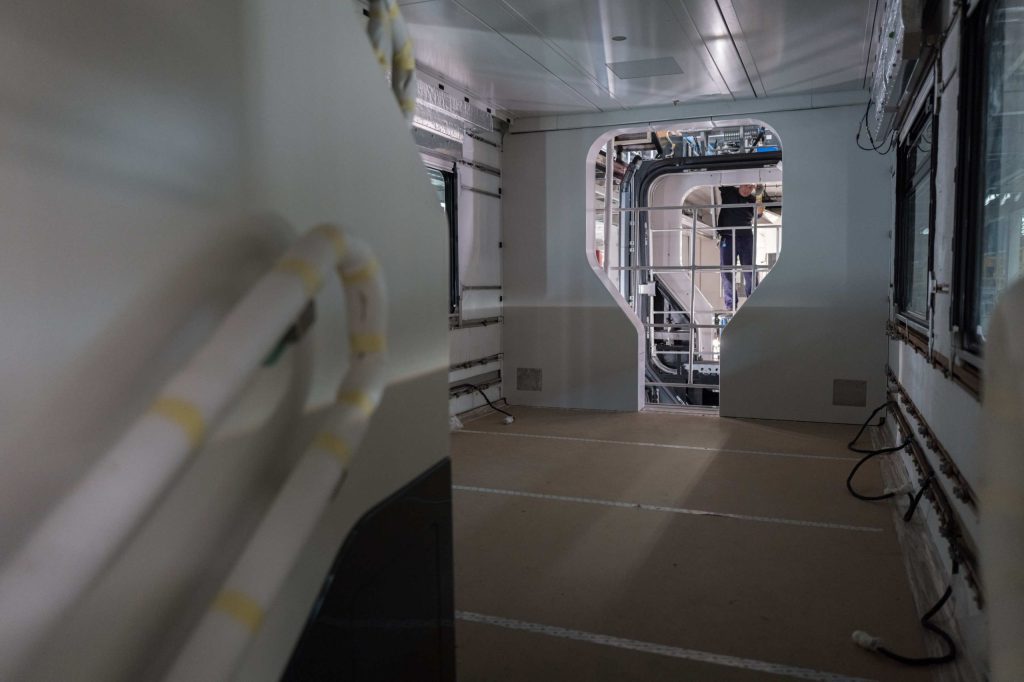

The Coradia trains follow seven well-defined technical steps: welding, painting, interior fitting, testing, quality control, inspections, and finally transport to the Grand Duchy. Each chapter leads to the conclusion of this beautiful story: the creation of a rolling masterpiece.

In the heart of the halls, the chassis is built from aluminium plates. Alstom welders assemble the various parts—base plate, side walls, intermediate plate, roof, and end plates—to form the vehicle body, before the Coradia receives its distinctive mark: the CFL’s red and white colors.

From spark to departure

Around 4,000 screws, nuts and small parts, between 79 and 144 km of cables, countless metal components, several axles, axle pins and motors, not to mention the seats and windows… After around three months, this impressive inventory gives rise to a Coradia 2400 series train.

A historic order

The CFL have ordered 34 Coradia Stream High Capacity trains to Alstom:

• 22 trains forming the 2400 series (three carriages) with 334 seats each,

• 12 trains forming the 2450 series (six carriages) with 692 seats each,

These trains can also be combined to form multiple units: 3+3 / 3+3+3 / 3+6. This is an undeniable advantage in meeting the exponential demand for public transport in Luxembourg and the border regions.

Currently, 15 Coradia trains operate as single units (3 carriages) on the Luxembourg rail network and to Arlon (BE). Since 15 October 2025, a multiple unit (2x3 carriages) has been operating between Luxembourg and Diekirch. At the end of this year, the CFL plan to put the first six-carriage 2450 railcar into service. By the end of 2026, other new-generation trains will gradually arrive in Luxembourg.

Seven times seven times seven times six times three times nine

Does this calculation give you a headache? Building a train is no simple mental exercise, but a complex process combining technology, craftsmanship and precision. After all, every train carries thousands of passengers on its rails.

Under the watchful eye of Alstom’s quality department and supervised by our expert colleagues from CFL’s TM (Trains and Equipment) department, including Mike Strotz (rolling stock procurement manager) and Christophe Kaut (project manager for the procurement of the 2400/2450 series), each Coradia undergoes rigorous testing before being authorised to join the Luxembourg fleet.

The final acceptance by the CFL is strict and structured: for three days, six specialists examine the train down to the smallest detail. ‘It has to be flawless – otherwise it doesn’t move,’ summarises Christophe Kaut. ‘If something is wrong, it has to be corrected.’

"Fun facts"

Did you know that the six-car Coradia (series 2450)...

• weighs 300.7 tonnes? One train car weighs as much as 10 elephants.

• is 160.6 metres long? That's the length of a line of 20 cars.

• has 692 seats? That's as many as the capacity of four airliners.

• has engines with a power output of 5.6 MW? That's equivalent to the power output of eight Formula 1 cars.

• is made up of 144 kilometres of cables? That's as long as 3.5 marathons.

Towing permitted

Have you always wondered how a brand new train leaves the factory to join the Luxembourg rail network? It is towed. Or almost. The first stage involves transport by lorry to the Spanish border, followed by traction from a freight locomotive. Officially, the train cannot yet run on its own.

Before transporting CFL customers, the Coradia railcar must prove itself on the Luxembourg rail network with thousands of kilometres of tests allowing for checks and other adjustments. Once these stages have been successfully completed, the train is ready for service.