At the Bettembourg-Dudelange terminal, the train of tomorrow’s logistics is already on the right track

Connected to major European rail corridors and economic centers, the Bettembourg-Dudelange intermodal terminal, operated by CFL terminals, is one of the cornerstones of logistics ‘made in Luxembourg.’ On site, the constant flow of trucks, the choreography of gantry cranes, and the movement of trains reflect the growing interest in this infrastructure.

Industry, automotive, textile, pharmaceutical, and even agri-food. Just a quick glance at the truck trailers parked on site is enough to grasp the wide range of sectors represented at the terminal.

Straddling the municipalities of Bettembourg and Dudelange, the 33-hectare site is a crossroads—a meeting point between road transport and the rail-based logistics ecosystem. A strategically located hub at the intersection of highways, whether asphalt or rail, managed by a team of 106 experts equipped with cutting-edge tools.

“We are clearly among the most modern sites in Europe,” says Laurent Erhard, CEO of CFL terminals. “The terminal is less than 10 years old, so it was designed from the outset with the best technologies for the sector. And the ongoing investments it receives support this vision.”

Upon arrival, truck drivers follow an automated process supported by CFL terminals staff: size checks, trailer inspections, weighing, parking designation—everything is done to ensure safety, quality, and fluidity at a terminal open 365 days a year, 24/7.

“This setup allowed us to handle an average of 325 trucks per day in 2024, with peaks of up to 600 trucks per day,” adds Laurent Erhard.

The terminal in key figures: • 3 gantry cranes, • 4 rail tracks of 700 meters each for combined transport trains, • Up to 12 combined transport trains per day, • 2 rail motorway platforms of 700 meters each, • Up to 16 trains per day on the rail motorway, • Annual capacity of 600,000 intermodal transport units (ITUs) — containers, semi-trailers, tankers, etc. • Storage capacity for 3,425 containers (20-foot equivalent units), • 840 parking spaces for semi-trailers.

Technology and decarbonization

Beyond the mosaic of trailers, containers, and tankers ready to be loaded, the terminal is recognizable from afar by its three gantry cranes, which transfer cargo to combined trains. Don’t be surprised to see their cabins empty while in motion—they’re remotely operated from a control center.

“Our four 700-meter loading tracks allow us to form complete trains that travel across Europe,” explains Laurent Erhard.

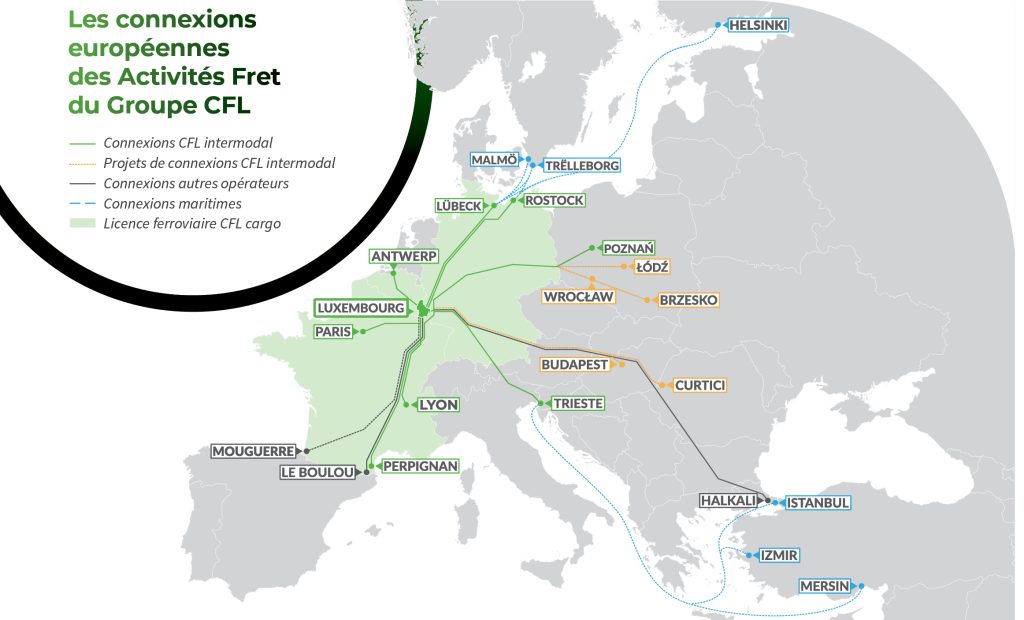

“We focus our efforts on the main European rail corridors with the goal of offering the best weekly frequencies,” says Barbara Chevalier, Director of CFL Freight Activities. “Experience shows that on routes where we consolidate volumes and optimize resource use, our offer is competitive, economically viable, and significantly contributes to reducing the carbon footprint of transport.”

400 fewer semi-trailers on the roads every day

Near the combined trains, yellow tractors silently maneuver semi-trailers. These four next-generation electric models are part of CFL terminals’ investments, supported by the European Union through the Connecting Europe Facility program.

Read also : Towards the Decarbonization of the Terminal

In just 45 minutes, they load/unload a train from the rail motorway connecting Bettembourg-Dudelange to Le Boulou in southern France—1,045 km covered in 15 hours.

“This unique infrastructure allows us to capture a significant market among manufacturers and road hauliers,” adds Laurent Erhard.

A concept that is gaining increasing traction, with an average of four round trips organized each day—meaning 320 fewer semi-trailers on the highways thanks to this train alone, in addition to the hundred transported via combined trains.

At the heart of logistics “made in Luxembourg”

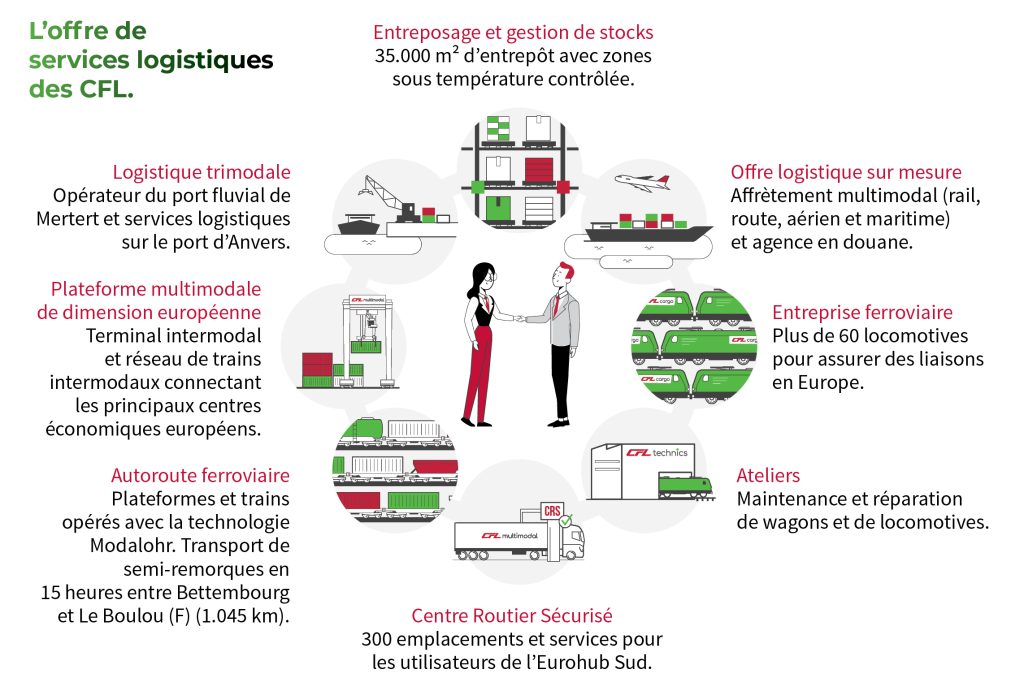

Opened in 2017, the terminal is part of a 100-hectare complex. This logistics hub in Luxembourg includes workshops operated by CFL technics, warehouses managed by CFL logistics, the Secured Truck Stop run by CFL site services, the shunting yard, as well as the Eurohub South logistics park.

“We have the right expertise and tools to promote the attractiveness of rail freight compared to road transport,” notes Barbara Chevalier.

While both transport modes complement each other in a multimodal approach, customers often still opt for the cheapest solution from end to end. Yet rail transport offers many advantages for rethinking the logistics chain—at the intersection of profitability and corporate social responsibility.

Did you know?

Compared to road transport, rail freight offers impressive advantages:

• 6 times lower energy consumption,

• 9 times fewer CO₂ emissions,

• 8 times less air pollution,

• 85 times fewer accidents.

Source: Rail Freight Forward