On track to the first CFL digital twin of a railway line

From Bettembourg to Volmerange-Les-Mines, line 60B will soon be equipped with a complete laser survey, a prerequisite for the installation of its digital twin. This large-scale operation, unique in Luxembourg and the Greater Region, reflects the leading role played by the CFL in BIM.

Small dots make big clouds. A year after becoming the first company in Luxembourg to achieve ISO 19650 certification, the CFL Group has just taken another substantial step forward in its Building Information Modeling (BIM) strategy, which began in 2017.

Carried out on the night of 29 to 30 October 2023, the innovative, high-flying exercise in question was designed to scan the whole of line 60B (Bettembourg – Volmerange-Les-Mines).

We’re talking about a quantum leap in the way we communicate in real time around a project.

Tom Gaspard, BIM Manager. CFL

“The digital twins of a building or infrastructure are at the heart of the BIM process, which makes it possible to create and manage high-quality, standardised information that can be shared between all the parties involved in a project,” explains Tom Gaspard, BIM Manager in the BIM Division of CFL’s Infrastructure Projects Department. “We’re talking about a quantum leap in the way we communicate in real time around a project, both internally and with external partners. Thanks to digital twins, we can simulate work very accurately and save time, money and, ultimately, improve quality for the customer or end user.

The benefits of BIM in the railway sector

While the CFL have been working for several years in Luxembourg to promote BIM and the collaborative approach it represents for the design and construction of buildings, the group is now making a move into the world of railway BIM.

This innovative process will enable the CFLs to benefit from the significant advantages of the BIM method for their infrastructure projects: optimised planning, a common database shared and completed by all the professions involved – all of which means that construction can be carried out efficiently in terms of resources (materials, time, budgets) and in the most sustainable way possible.

The country’s first railway line and its associated equipment, scanned using LASER, extends over 7 kilometres. “We chose it because it’s a critical length for carrying out a first exercise of this kind”, adds Tom Gaspard.

A “3-dimensional” photograph

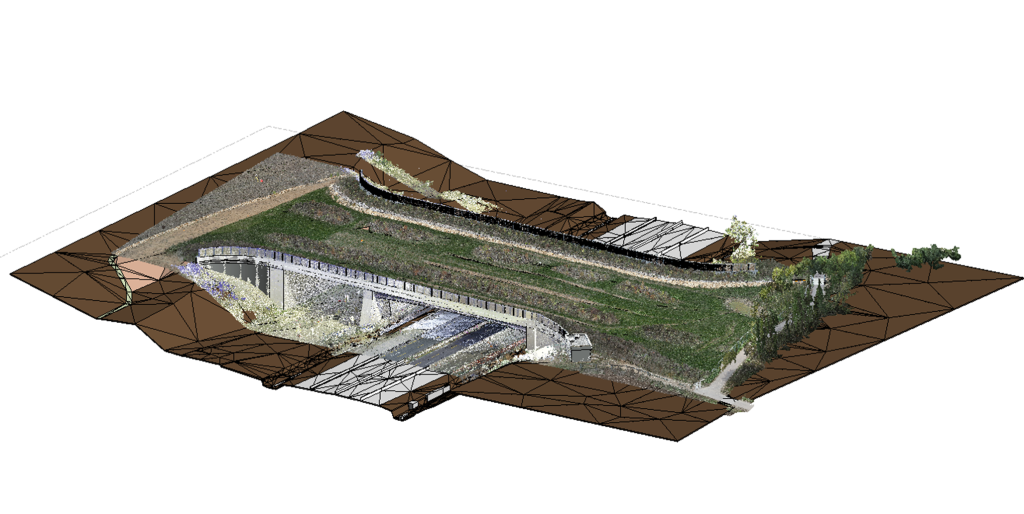

To create the digital twin of line 60B, “point clouds” were recorded throughout the night, as a car packed with technological tools passed by, mounted on a carriage pulled by two CFL “Robel” machines (for each direction).

“This specially equipped car projected several thousand laser flashes during four passes at an average speed of 25 km/h. The reflection of the laser on the elements present on site makes it possible to calculate their position and characteristics and, subsequently, to create a three-dimensional image of the entire line”.

A treasure trove of ideas for future work

The final result will enable the railway line to be viewed on screen with millimetre-level accuracy. “We go beyond the three-dimensional representation by adding several layers of information relating to data classified according to the nomenclature of the site.”

A set of interlocking data which, once processed, represents a treasure trove for the CFL Infrastructure Manager, for example to simulate and optimise modernisation work or studies of the clearance gauge for trains as part of railway infrastructure maintenance work, to continue to ensure the safety of CFL staff and their customers – an absolute priority for the CFL.

Any subsequent modification to a building or infrastructure represented in the digital twin can be directly integrated into the latter without having to carry out a new Laser survey on site.

In-house collaboration and local expertise

The success of the operation is the result of collaboration between the CFL BIM team and its colleagues from the Infrastructure Manager, including the Infrastructure Maintenance and Infrastructure Operations departments, to ensure, among other things, the safety of operations and guarantee normal rail traffic at the same time.

“We are working on this project with two partners, one of whom is based in Luxembourg. The first is in charge of data capture with this specially equipped vehicle, and the second is in charge of data processing. With this type of exercise, we’re helping to gain local experience and increase the expertise of the entire BIM chain within the sector”.

Thanks to the feedback provided by this laser survey, expected in early 2024, the CFL will be able to consider similar operations on other existing railway lines or lines under construction, such as the future new double-track line between Luxembourg and Bettembourg, which will also be 7 kilometres long...

What is possible on existing lines is obviously also possible on projects in their preparatory phase. The CFL are pursuing several projects using the BIM process right from the start, such as the future Troisvierges P+R.

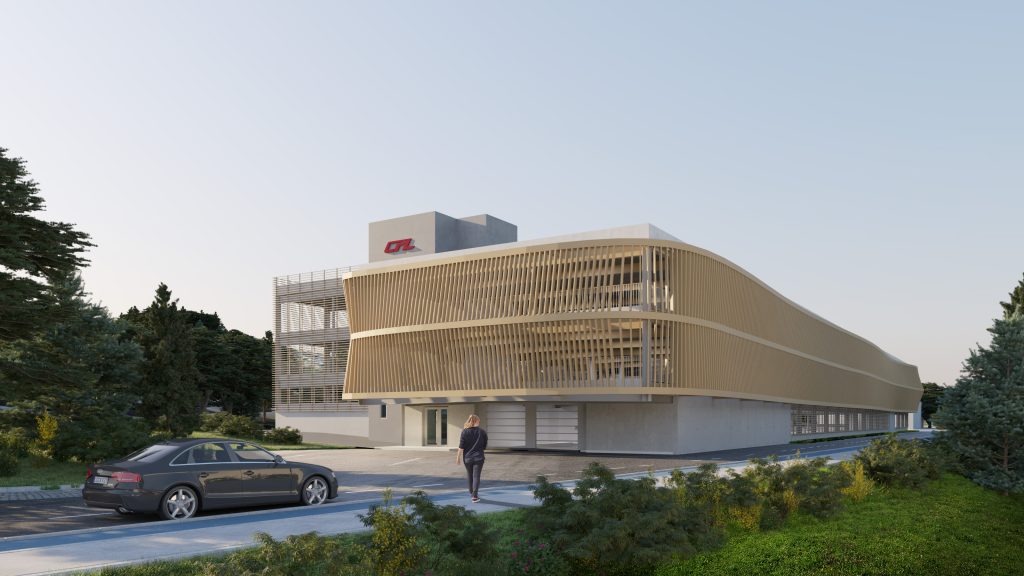

The renovation of the group’s head office, a project that has been developed using the BIM approach since the tender phase in Luxembourg.

Ultimately, the CFL’s ambition is to create a complete digital twin of the rail network and its buildings by 2035. The BIM method is more than just a work process; it has become a work standard.