OA14: one step further in the construction of the extraordinary bridge

It was not a day like any other for the team around Rui, the CFL project manager of the new line between Luxembourg and Bettembourg. The team had been looking forward to this day for several weeks. Last week, the day finally arrived and the fruits of months of work paid off.

The reason for the team’s anticipation and excitement is the completion of the assembly of two of a total of 4 arches, which will later carry one of the biggest “bow-string” railway bridges in Europe. More precisely, it is the assembly of the apex elements, which puts a combination of concentration and anticipation on the faces of more than 20 people involved onsite. It is the last element of 9 components which constitute one of the two lower arches. When the 60-tons heavyweight is set into place, it eventually proves whether the prior work was done with millimetre precision.

Precise work in several steps

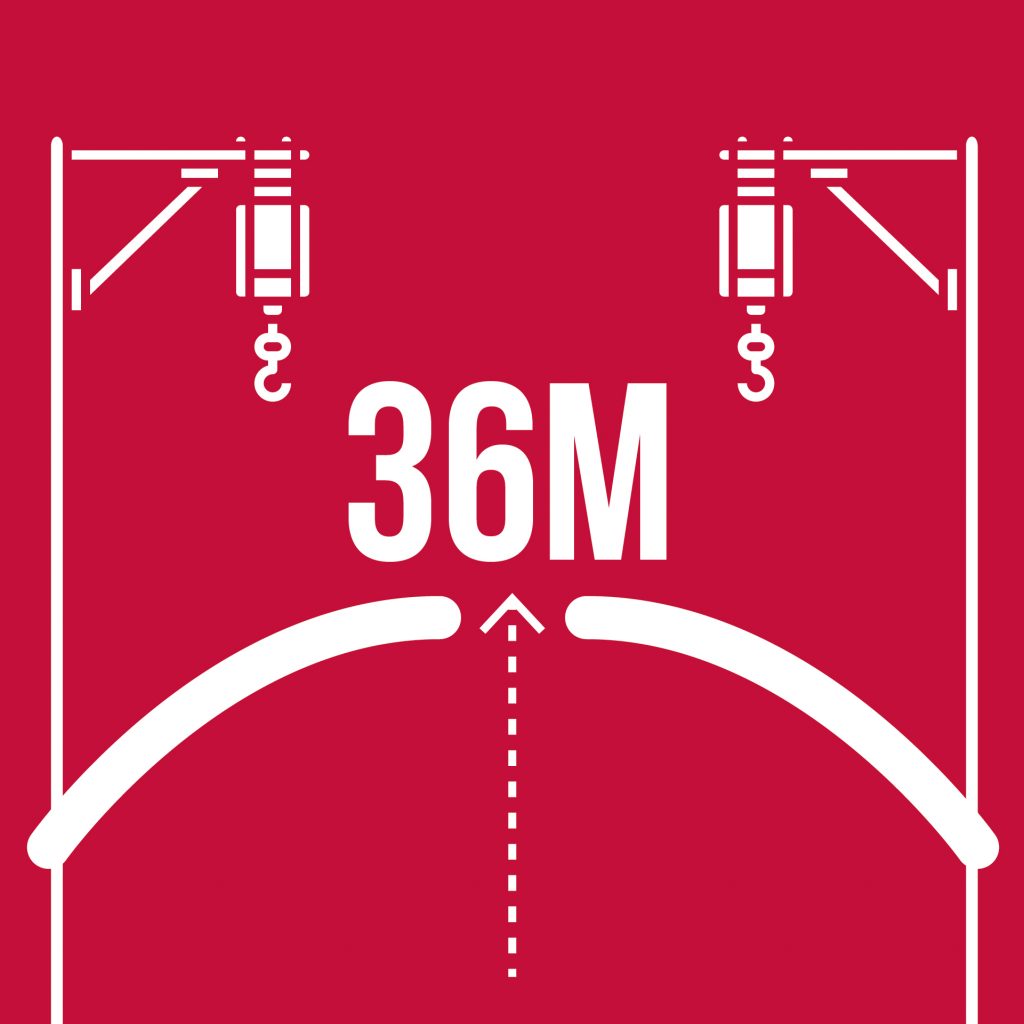

Two cranes are needed to lift the 20-meter-long and 2,3-meter-high elements to a dizzying height of 36 meters. It is real millimeter work. After exact measurements, the metal elements, which are delivered in overlength, are tailor-fitted onsite to make sure they can be perfectly joined with millimeter accuracy.

This is possible by teamwork, or more accurately, by coordination between workers on the ground in collaboration with the colleagues up in the workmen baskets in the air. Once the element has been provisionally assembled, it is clamped together and a final check is done in order to make sure that the elements were positioned accurately and according to the installation plans. If this is the case, welders literally let the sparks fly: first from the outside, then from the inside of the elements.

Both apex elements were installed in just one day. The exact positioning of the two cranes’, an essential condition to ensure the safety both for the workers on site and for the already existing metal construction, took one whole morning. In the afternoon, the installation and the welding of the apex elements proceeded.

Each arc is composed of 9 elements

The elements are installed from the lateral extremities

20 specialists were on site for the assembly of the lower arches’ apex element

Two mobile cranes capable of lifting 400 tons were used

The apex element in overlength is tailor-fitted before being moved to its final position

For the assembly at a height of 36m, the element is picked up by cranes

After the installation the elements are clamped, welded and colored

After the assembly of the lower arches, work is now continuing on the two upper arches. At the end of 2022 the 5,850-ton bridge (weight without the concrete roadway slab) will finally be moved across the motorway to its final location by means of so-called KAMAGs.

The OA14 in numbers:

With a 200-meter span and a 40-meter height, the metallic structure, whose assembly started in mid-October 2021, consists of two tension bands, four arches and 24 hangers. The different caisson elements vary in length from 20 to 24 meter and weigh between 60 and 120 tons each.

(You missed the first article about the OA14? Learn more about it here)