Simply explained

-

11 Dec. 2018 • 2 minutes

11 Dec. 2018 • 2 minutesCall Center and Information Service: here for you!

Read more -

17 Oct. 2018 • 3 minutes

17 Oct. 2018 • 3 minutesThe safety line

Read more -

02 Oct. 2018 • 3 minutes

02 Oct. 2018 • 3 minutesBuses, a part of the CFL well worth discovering

Read more -

19 Sep. 2018 • 2 minutes

19 Sep. 2018 • 2 minutesBarrier-free travel – the European concept “Design for all”

Read more -

04 Sep. 2018 • 3 minutes

04 Sep. 2018 • 3 minutesrailway closure – behind the scenes

Read more -

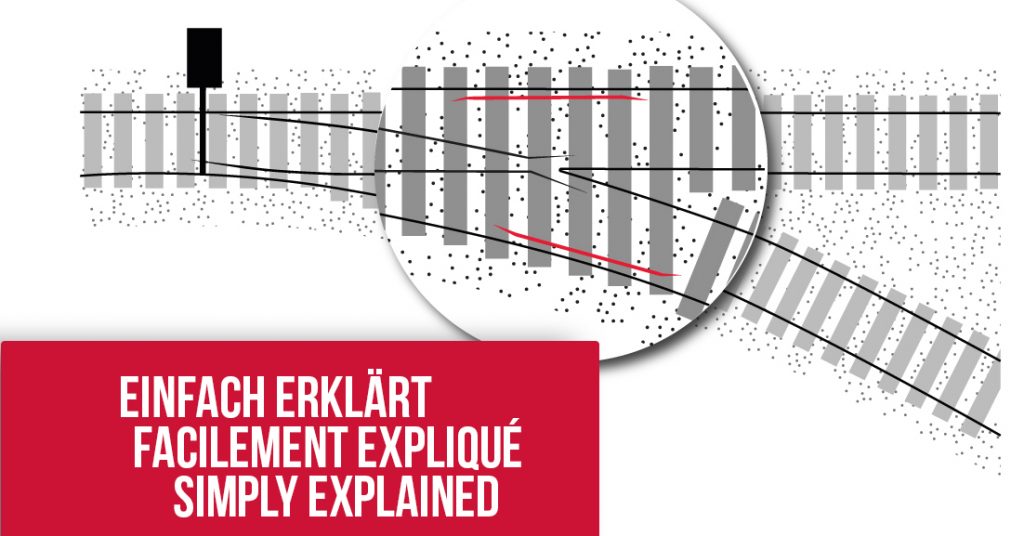

03 Jul. 2018 • 1 minute

03 Jul. 2018 • 1 minuteSimply explained : switches

Read more -

20 Jun. 2018 • 1 minute

20 Jun. 2018 • 1 minuteThe track maintenance

Read more -

12 Jun. 2018 • 1 minute

12 Jun. 2018 • 1 minuteIn the driver’s cabin of a KISS Stadler

Read more -

15 May. 2018 • 1 minute

15 May. 2018 • 1 minuteThe rolling highway

Read more -

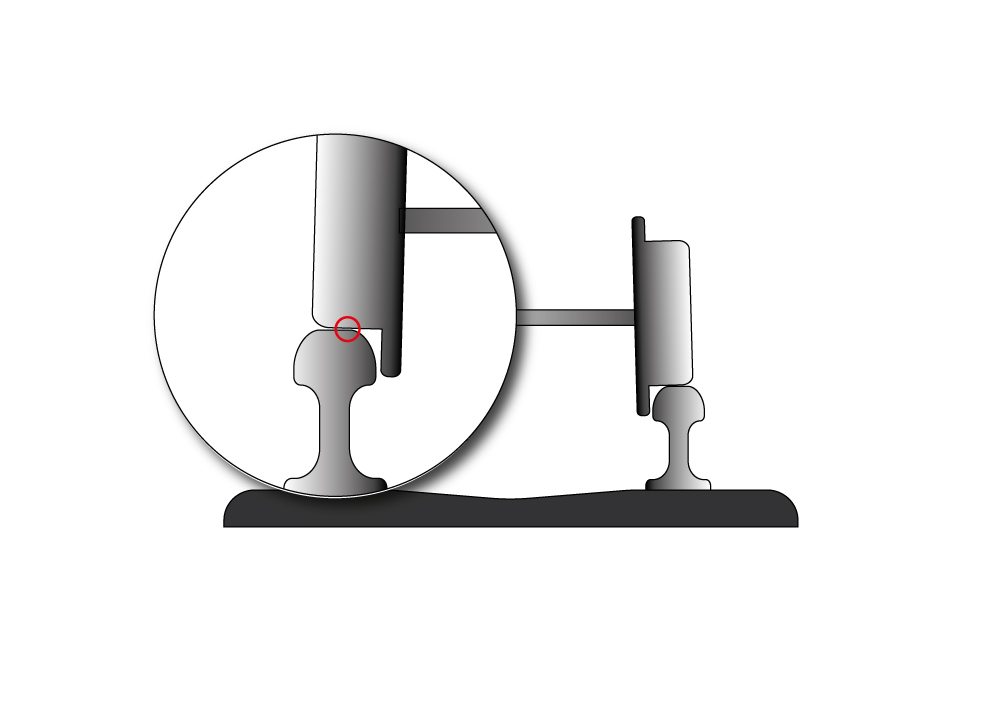

30 Apr. 2018 • 1 minute

30 Apr. 2018 • 1 minuteThe track

Read more -

28 Mar. 2018 • 1 minute

28 Mar. 2018 • 1 minuteCFL’s train-wash-station

Read more -

05 Mar. 2018 • 1 minute

05 Mar. 2018 • 1 minuteAfter 20 years of loyal services : the complete overhaul of the Z2

Read more